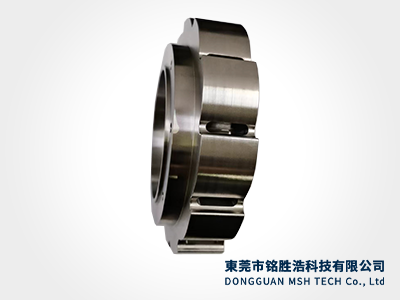

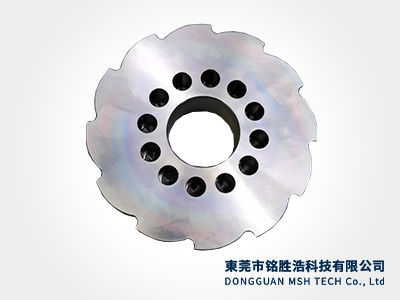

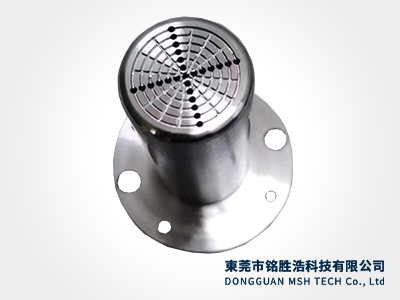

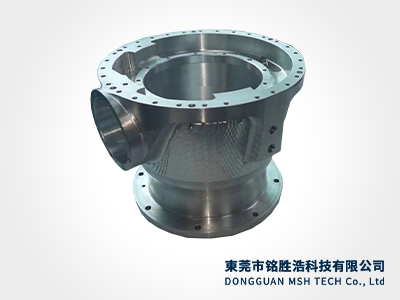

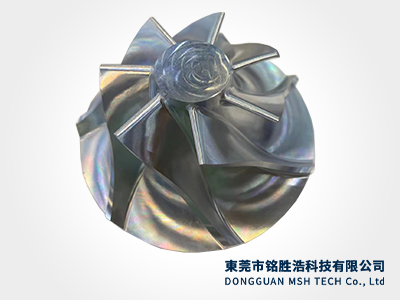

Electric vehicle production takes off, there will be an increase in demand for machined components such as blade carriers, gear wheels, planet carriers, shafts, transmission components, a variety of battery cells and modules, and compressors.

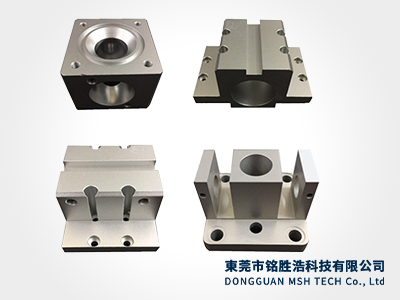

Most internal parts of autos need CNC machining, turning, and milling. On the other hand, most of the external parts are sheet metal parts, which are mainly completed by laser cutting, CNC bending, and stamping. We support small production runs as well as large ones, with high accuracy and quality.

Common materials: aluminum alloy, zinc alloy, magnesium alloy, stainless steel, steel, etc.

Surface treatment: anodizing, powder coating, painting, sandblasting, electroplating, laser marking, silk screen, polishing, etc.