The Company

MSH TECH was established in 2012 with 35000 sq.ft of workplaces. Full capabilities to cater for one-off prototypes and small, medium, and high-volume production runs.

Quick facts about MSH

• Core Services: CNC machining, Manual machining, Supply chain.

• Applications: Automation, Semiconductor, Automotive and Medical industry, etc.

• Part Materials: Steel, Aluminum, Titanium, Brass, Copper, Stainless steel, Plastic, etc.

• Location: Dongguan, Guangdong, China

• Employees: 65

Outsourcing Partner (Vacuum casting, 3D printing, etc.)

• DONGGUAN LIKAI Prototyping Co., Ltd

• HAIYI (Hongkong) Mould Co., Ltd

• SHENZHEN CHENXIN Sheet Metal Fabrication Co., Ltd

Our Mission

MSH TECH provides rapid, reliable, and quality services while working closely with customers helping control related manufacturing cost and finding practical manufacturing solutions in assisting them with their customer demands.

Our Value

• Earn trust by providing high-quality parts and customer service orientated.

• Be accountable for our actions.

• Be committed to innovating our procedures to save costs.

• Remain open and proactive in communication.

• Contribute to the environmental sustainability.

• Enrich the lives of our employees.

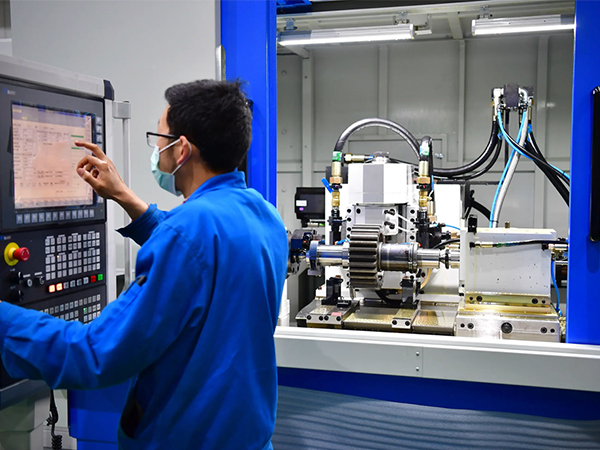

Professional Team

With a progressive management structure, our team is here to bring the highest standards of professionalism to every strategic partnership. We are committed to maintaining and improving the professionalism, creativity, and morale of our team.

In the past decade, we have trained professional teams to handle one off, batch and mass production. All of them are experts in their field and have built up years of experience, successfully running projects with our international customer base.

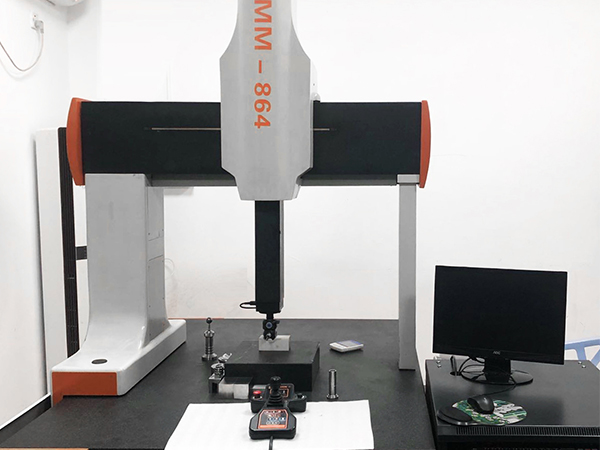

Quality Assurance

MSH is focused on delivering excellence in performance, flexibility, and technology that exceeds customer expectations for quality, delivery, and service. We adopt flexible quality control methods to deal with the production of various-quantity orders to reduce the cost of customers while ensuring the quality.

ISO DIN-2768-1-fine standard is commonly used in our works. Therefore, our inspection processes are incredibly strict, and regularly calibrate our precision-inspection equipment.